Scale Cannabis Cultivation Profits With Vertical Grow Racks

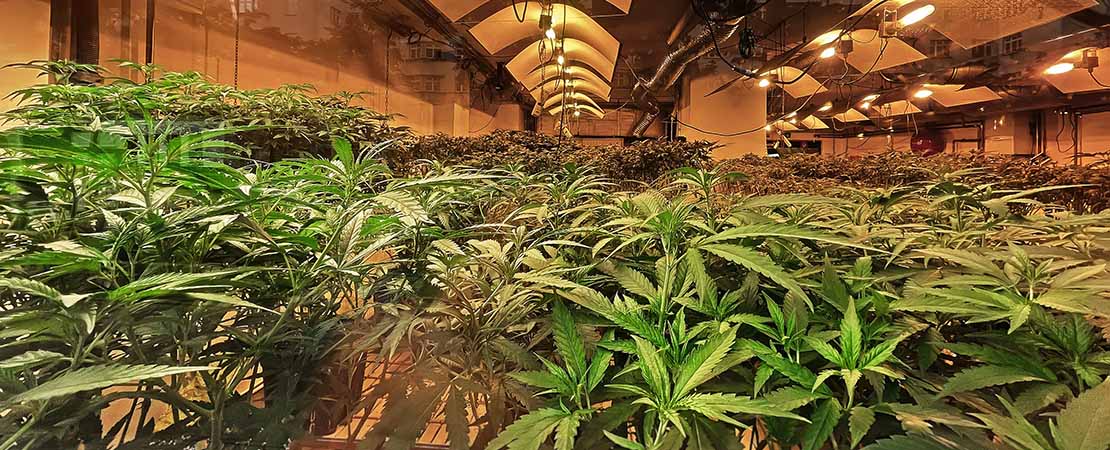

The use of vertical grow racks is gaining popularity as a viable method for urban marijuana cultivation. Vertical farming refers to the practice of growing crops in vertically stacked shelving.

This cultivation method allows you to better use your available overhead space and get more bang for your buck.

Cannabis farming has been one of the main beneficiaries, if not the pioneer, of this farming method, allowing growers to make the most of their available indoor grow space.

Vertical farming enables you to grow plants in the confines of your apartment, warehouse, or skyscraper. Whatever indoor space you’ve designated, there’s a vertical system solution to help you maximize your return on investment.

Vertical grow racks are essential components in improving your cannabis cultivation profits.

Six Top Ways Of Cultivating Cannabis Profits With Vertical Grow Racks

Primary ways vertical farming increases your cannabis operation profits include:

1. Eliminates Wasted Space

Renting or buying a warehouse to start an indoor cannabis grow operation can be expensive. Because of the cost, you must ensure that you are utilizing every square inch of available grow space so that you are getting the most out of your money.

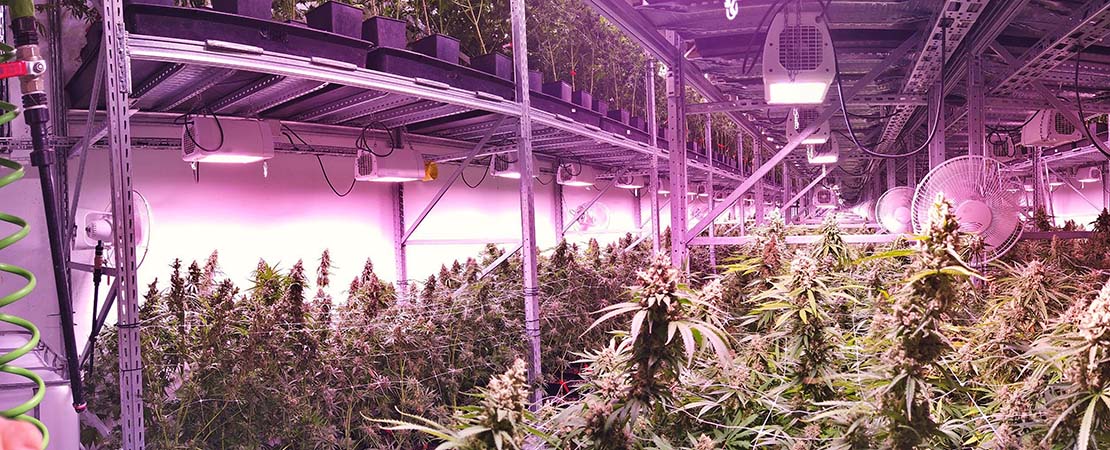

Vertical racks help to optimize space both vertically and horizontally by creating additional levels of plants and eliminating empty aisles between tables.

Stationery racks create static aisles, which are valuable grow spaces. Using mobile vertical grow rack systems allows you to condense your systems together, creating only one aisle in your grow space.

Moving these racks to create aisles is made simple thanks to our mobile components. These mobile components include; carriages atop flange wheels, a bar track that the carriages sit on that allows for smooth movement and mobility, an aluminum shaft that runs the length of the carriage, and a mechanical gearbox with three different gear ratios.

MMI Agriculture mobile carriages have a single-spoke mechanical assist handle that allows your staff to quickly move the mobile carriages to create aisles and get work done.

Additionally, vertical grow systems can be customized to have as many grow tiers as needed, depending on design, demand, and municipal regulations. The multiple levels increase the canopy cover per square foot by two to three times compared to horizontal farms. They make use of available overhead space that would otherwise be idle.

2. Vertical Grow Racks Save On Climate Control Costs

The high costs of vertical farming are due to utility bills such as electricity and water bills. These utilities are critical in powering systems that simulate the outdoor environment required for proper cannabis plant growth.

For example, you need to install ventilation systems, including ACs, exhaust systems, exhaust fans, and CO2 burners. These systems are installed in your space to provide the air quality required for canopy growth.

With well-managed aisle and overhead space using vertical systems, the electricity that powers these systems, cooling and heating your entire facility, could be better utilized.

Vertical grow systems fill this underutilized space with canopies, putting your heavily invested ventilation infrastructure to good use.

Hydroponic trays are also used in vertical systems. Hydroponics farming is a type of soilless cultivation that uses 90% less water than traditional methods. A hydroponics irrigation system uses nutrient-rich water to meet the nutrient requirements of the plants. The systems recycle water and nutrients, saving money on fertilizer and water.

Moreover, the irrigation is automated so that the plants can be watered easily. The systems also employ an ebb and flow irrigation method, which is low-cost and requires no technical setup. It conserves both water and electricity.

When used in conjunction with MMI Agriculture vertical grow racks, this system ensures that you continue to save on operating costs, while maximizing profits from your marijuana plants.

3. Better Growing Conditions

Growing marijuana indoors with vertical farming systems creates a better growing environment for your marijuana plants than growing outside. The indoor environment is not limited to seasons such as winter and summer, nor to changing levels of sunlight.

Vertical systems should be housed in sanitized environments that give your crops the best chance of growing without being affected by diseases or pests.

Your crops are grown in closed environments where the soil is rarely used. If soil is used, it is sanitized to prevent plant contamination. Hydroponic farming entails planting crops in coconut husks and then allowing the roots to thrive in nutrient-rich water, keeping fungi and pests at bay.

Ventilation systems also reduce the possibility of unintentional pollination. When female plants are pollinated, they can degrade the quality of their buds.

Furthermore, you should avoid vertical wood shelving because it can harbor disease-causing molds and pests.

Consider MMI Agriculture steel racks; unlike wood, they do not provide a conducive environment for pests and disease to thrive.

Because of the increased coverage per square foot, you can allow for more space between your marijuana plants, allowing your canopies to flourish.

Good spacing and disease prevention ensure that you harvest high-quality cannabis buds from your operation.

4. Increased Yields And Profits

Standard outdoor farms allow their farmers to grow crops on large expanses of land spread out horizontally. Vertical farms, however, allow their farmers to expand their horizontal grow space vertically, giving them significantly more square footage to grow off of.

The additional grow space going up increases your canopy coverage for the same area of land, resulting in higher yields.

Growing crops in an indoor operation using a vertical grow system provides a unique opportunity to plan out your farmland. It gives you a clearer picture of what to expect from your investment…but how so?

Our drafting team, using the most up-to-date CAD technology, will create a layout based on your available grow space. By using our drafting team to create your layout, you are ensuring that your grow operation is maximizing both your grow space and your investment.

The vertical farming technology leverages Controlled-environment agriculture (CEA) to create the ideal environment for your canopies to grow. CEA is so effective it can help you determine the terpenes and color of your cannabis plants, giving you control over the end product.

Moreover, cannabis software technology allows you to monitor your plant growth in real-time, ensuring compliance and quality.

Overall, CEA technology, combined with the convenience vertical farming systems provide in tracking your products, can help improve your bottom line from cannabis cultivation.

5. Safer Workplace

Vertical racks improve worker safety in an indoor farm while also helping you meet OSHA standards. A pleasant working environment aids in the retention of skilled workers, thereby increasing productivity and, as a result, profits.

MMI Agriculture offers mobile carriages equipped with anti-tip features that prevent shelving from falling over, ensuring the safety of your workers in the event of seismic activity. This also helps you stay in compliance with regulations in areas more prone to seismic activity where you’ve set up your grow space.

We also provide an optional ADA ramp to eliminate tripping hazards. This enables your employees to have smooth access to the carriages via carts or ladders.

Vertical grow system manufacturers have developed solutions that have resulted in increased worker productivity and made access to plants located on high elevations easier. For example, at MMI Agriculture we have a retractable mezzanine walkway. This patent-pending product enables your staff to reach the upper decks comfortably and tend to the plants.

The walkway can be installed at any height and accessed via ladders or scissor lifts through the front aisle. It is made of fiberglass and resin composite to withstand heavy traffic while keeping your workers safe.

Furthermore, the shelving is braced with diagonal and horizontal beams to support the weight of your plants and employees.

Vertical systems are designed with worker safety in mind, giving your staff the peace of mind they need to focus on caring for your canopies.

6. Allows For Automated Farm Operations

A skilled labor shortage has plagued the market, causing production delays and inefficiency, leading to loss of money. Indoor vertical farming establishes a platform for automating your cannabis cultivation, filling labor gaps, and increasing productivity.

In our article on four trends in vertical farming, we cited that incorporating Artificial Intelligence (AI) and automation robots into your vertical farming to produce crops results in a more than 200 percent yield increase.

AI and machine learning allow machines to study your crops’ development and, over time, modify the conditions and nutrients available to your plants. This advancement has the AI producing unique high-terpene and flavorful marijuana plants for your customers.

The robots tend to your plants 24 hours a day, seven days a week, providing you with a dependable workforce and thus improving your bottom line. The vertical systems are made ready to receive these additions with sturdy frames and tracks, and hydroponic trays to accommodate automated irrigation.

Alternatively, you can deploy sensors and timers to control the various equipment in your grow room. This automation frees up your staff to focus on pruning, inspection, and harvesting your crops.

Automating operations on your vertical rack systems will give you a competitive advantage in labor output, thereby scaling up your profits.

Install The Right Vertical Grow Racks To Help You Cultivate Cannabis Profits

MMI Agriculture is a leading manufacturer of vertical farming systems custom-designed to fit your growing space. They are designed with safety in mind and to work with any hydroponics system and type of lighting.

Whatever your vertical system requirements are, we have the experience and equipment to assist you in creating your ideal cannabis grow space.

Contact us today to discuss how we can collaborate to cultivate cannabis profits using vertical farming systems.