A Complete Guide To Setting Up Ideal Cannabis Grow Rooms

Cannabis – both marijuana and hemp – is quickly becoming the most prominent cash crop in the United States. And deservedly so; hemp can be used to manufacture a wide array of products. It also grows very vigorously and easily, thus requiring cannabis grow rooms with less specialized care than most other crops. This makes it a lot cheaper to cultivate and ultimately more profitable.

Cannabis and hemp can be cultivated both outdoors and indoors in cannabis grow rooms. Today, many farmers are opting to cultivate their hemp indoors. Planting crops in an enclosed space allows you to set up a controlled environment and provide the optimum conditions for their growth. It also, for the most part, protects them from pests and diseases, translating to all-round healthier, more productive crops.

That said, there are a number of challenges facing indoor cultivators. One of the biggest challenges is limited cultivation space. Most cannabis grow rooms are quite small, making it hard to run a large-scale operation.

One solution to the issue of limited space is our vertical grow racking systems. Our products utilize the vertical space in your grow room and allow you to plant your cannabis and hemp in multiple tiers. This will help double, and even triple, your yields.

In today’s feature, we’ll look at what the ideal marijuana grow room looks like. We’ll also go through some of the ways you can incorporate our vertical farming equipment in your commercial grow space.

What’s In The Ideal Cannabis Grow Room?

What makes for perfect cannabis grow rooms? Providing your plants with the optimal conditions they need to thrive will ensure they grow healthy and productive. The typical indoor commercial grow room has a number of essential features: lighting, vertical grow racking, humidity and temperature control, and proper air circulation.

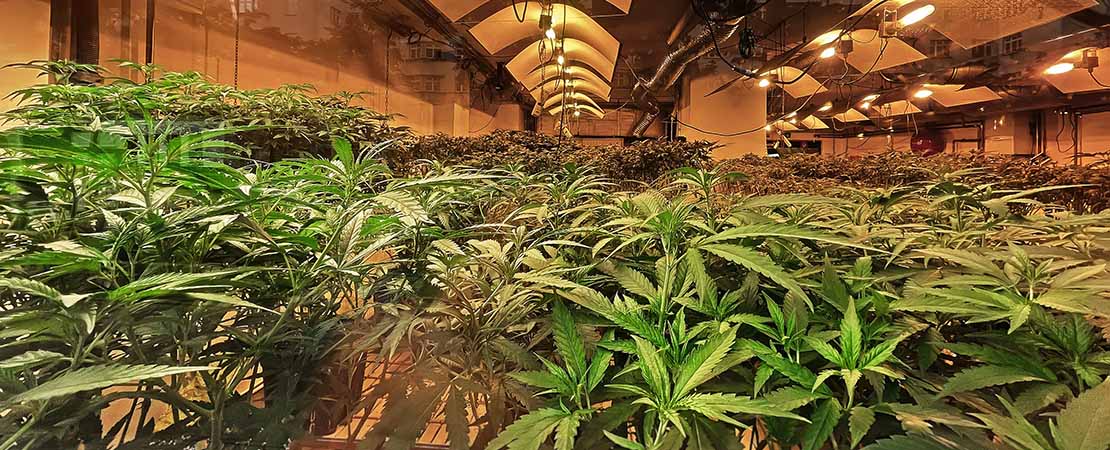

1. Lighting Your Grow Room

Lighting is one of the most crucial aspects of a well-designed, profitable grow operation. It is imperative that each cannabis strain is provided with an adequate amount of light to ensure enhanced growth and optimized yields.

When setting up a marijuana grow room, the rule of thumb is to use bright but not too bright lights. Before choosing a set of lights, you’ll need to consider the type of plants you’d like. Different lights cause plants to grow differently; for example, certain light spectrums result in tall, lanky crops, and others in squat, bushy ones.

Many commercial cannabis farmers go for LED grow lights for their cannabis grow rooms that allow users to customize the light spectrum they expose their plants to. Such lights will help you fully optimize the growth of your hemp plants. That said, it’s crucial to make sure you’re not exposing them to too much light.

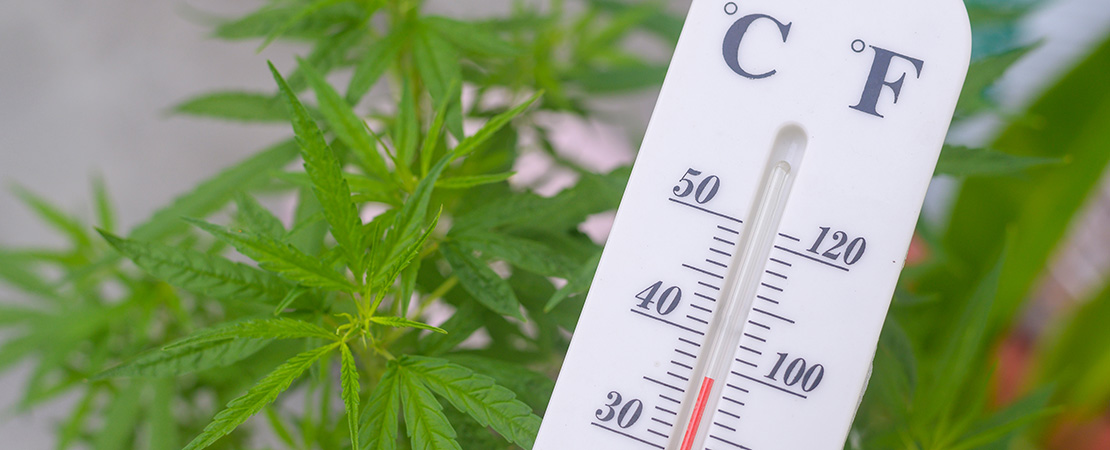

2. Make Sure The Temperature Is Just Right

The temperature of commercial cannabis grow rooms needs to be optimal for your plants. If it’s comfortable enough for you, it’s probably okay for your cannabis as well. A cold grow room will hamper germination and create a damp environment, putting crops at risk of mildew and mold.

Insulate your cannabis grow room as much as possible. Instead of putting on a heater, run your overhead lights for 18-24 hours a day. (Running lights for this amount of time will be much cheaper than running a heater for 5-6 hours.)

Another factor that many farmers fail to consider is cold nutrients solution. Chilled solution will shock your plants, slow down physiological processes, and ultimately stunt growth. Keep your reservoirs elevated from the floor to minimize heat transfer. You can also use an aquarium heater that will raise the reservoir’s temperature without damaging the nutrients.

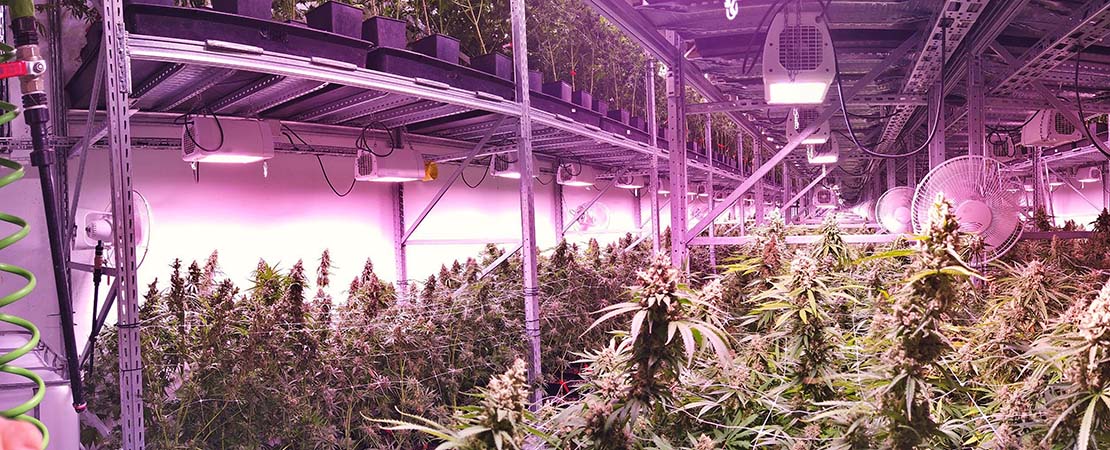

3. Setting Up Vertical Farming Equipment

Vertical farming equipment has become a commonplace fixture in most commercial marijuana grow rooms today. Vertical equipment allows you to take advantage of all the vertical space in your grow room. Setting up a cannabis vertical grow room will allow you to plant your cannabis and hemp crops in multiple tiers.

When setting up a commercial grow room, fitting it with vertical farming equipment will help maximize yields. We’ve developed numerous vertical farming products designed to fit every cannabis grow room layout. Let’s look at some of them.

-

Mobile Carriages

Our mobile carriages work in conjunction with our vertical grow racks to help eliminate wasted space created by the necessary aisles needed for non-mobile systems. Equipped with a single-spoke gearbox with 3 different gear ratio options, these carriages effortlessly move back and forth. If you’re really interested in maximizing your grow space, it’s an absolute necessity that you go mobile.

-

Vertical Grow Racks

While it’s important that you utilize our mobile capabilities to increase your canopy and your yields, it’s equally as important to use our vertical grow racks, as well. Vertical grow racks sit on top of the carriages, thus allowing them to be moved back and forth. Our grow racks come with the rebars to help support your grow trays, as well as to hang your lighting from. They are made up of 14-gauge steel, thus illustrating their strength and durability.

These grow racks can be stacked up to 21’ high and are the best way to double or triple your yields.

-

Tabletop Caster Units

Our tabletop caster units are used in rooms that don’t have enough space for vertical farming equipment. They can also be used during the germination stage before the seedlings are transplanted. These units have caster wheels, making them easy to move from one room to another. What’s more, they can also be optimized to accommodate multiple tiers.

4. Choosing Pots For Your Cannabis Plants

The containers you grow your hemp and cannabis in will largely determine how they grow and develop. There are many different kinds of grow pots to choose from. Knowing the different materials available to you will help you decide what’s best for your plants.

Plastic containers are used quite commonly: they are inexpensive and can be built to provide good drainage. They are, however, not very durable. Ceramic and terracotta plant pots are another option. These pots help regulate temperatures but often have poor drainage.

Hemp fabric grow pots are grabbing everyone’s attention today. Although these containers are made using thick fabric, they hold plants and soil really well. They also provide great aeration and drainage. They may, however, be subject to wear and tear more than other containers.

Regardless of the containers you choose to grow your plants in, our vertical farming equipment can support them.

5. Can You Access All Your Plants?

Access is another important factor for all cannabis grow operations. What’s the point of going high with your racking if you can’t reach the tiers on the top? One of our main goals is to help you choose the ideal cannabis grow room design without compromising on plant access.

That’s why we designed the retractable mezzanine walkway. This elevated decking makes it possible for your workers to access higher tiers in the grow room without having to climb up and down a ladder. The mezzanine rolls out and creates a walkway when an aisle is created. When not in use, the mezzanine rolls back to its resting place, which is located underneath the adjacent grow tray.

6. Ventilation And Air Circulation

When setting up a commercial cannabis grow room, you’ll need to ensure your plants always have a gentle breeze going around them. Providing proper circulation and plenty of fresh air helps plants grow faster. Good airflow also protects your crops from mildew and mold infestation, bud rot, spider mites, and fungus gnats.

You’ll need to create a gentle breeze that washes over, through, and under your plants to ensure humidity remains at optimum levels. As your crops begin to flower, you will need to control the aroma in your grow room. Installing a powerful, oscillating fan or two will get the job done.

Besides ensuring proper air circulation in the grow room, you should also provide an avenue for hot air to escape. It might get too hot in the grow room, and ventilating your large cannabis grow room will ensure all this heat is directed away from the plants.

7. Provide A Reflective Environment For Your Plants

As we’ve already mentioned, light plays a vital role in developing strong, healthy and productive cannabis crops. No matter how many nutrients you provide your crops with, they won’t be able to really flourish unless they’re receiving adequate light.

Placing a reflective material over your walls is a simple trick to help ensure your cannabis plants get all the light they need. You could also paint your walls a bright white to reflect light on your plants. If you’re looking for an easy way of squeezing out the most yields from your plants, make the walls and other surfaces in your grow room reflective.

8. Let’s Talk Humidity

Although humidity generally doesn’t cause too much trouble for developing crops, you should always ensure it’s neither too high nor too low. Remember, your plants will require different levels of humidity at different stages.

For example, optimal humidity during the vegetative state is around 40%-60%, during flowering 40%-50%, and in the final weeks about 40%-45%.

As mentioned earlier, proper heating, insulation, air circulation and ventilation will keep the humidity levels in your cannabis grow room controlled.

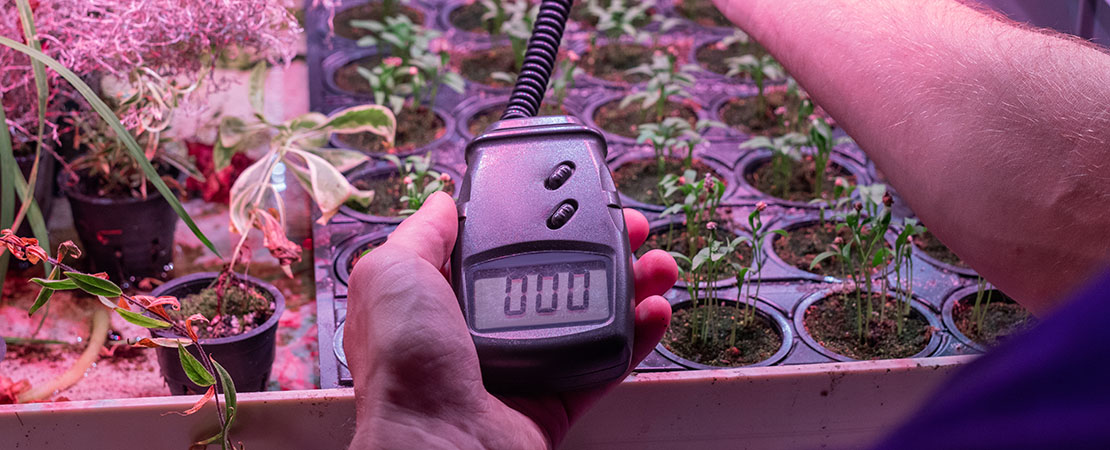

9. Provide Adequate Carbon Dioxide

Plants use carbon dioxide to generate food in a process called photosynthesis. The more carbon dioxide present in the room, the more food your cannabis plants manufacture. This translates to higher overall yields.

There are numerous ways in which you can supply carbon dioxide in your grow room. One of these is a carbon dioxide tank which you can use to pump CO2 into the room. You could also leave dry ice to melt near/around your plants or buy canisters that “leak” carbon dioxide into the room slowly over time.

Remember to limit carbon dioxide supply when lights are off. It’s also advisable to buy a meter to monitor CO2 levels in the air in your commercial grow room.

10. Keep Your Indoor Grow Rooms Safe and Tidy

Many farmers make the mistake of filling their indoor grow rooms with too many plants in a bid to maximize their yields. This results in a cramped grow space that’s difficult to maneuver around.

Ask yourself, how much room do cannabis plants need to grow?

One of the most crucial features of a good commercial cannabis grow room is safety and tidiness.

Ensure there is enough space in between aisles such that people don’t have to squeeze themselves through. Keep all the lights and growing accessories anchored either to the ceiling or the vertical racks to minimize the risk of anything falling and injuring someone.

Prioritize your safety and that of other people working in your commercial grow room.

We’ll Help You Set Up Profitable Commercial Marijuana Grow Rooms

We understand that setting up a cannabis grow room may be a bit convoluted and complicated. There’s so much you need to keep in mind: lighting, ventilation, insulation, reflection and more. We’re dedicated to making this process easier for the cultivation of any indoor crop.

We offer free design services and show all our clients the best way to plan their grow rooms. We also evaluate our clients’ grow rooms and help them develop a layout that fits their space. If you’re thinking about expanding your commercial cannabis grow operation in 2022, feel free to contact us or request a quote.