Versatile and Durable: Grow Shelves Vertical Growing Systems For Cannabis Cultivation

When it comes to indoor growing, there’s a lot to consider when acquiring your cultivation equipment.

For example, your vertical grow shelves are major equipment in your indoor grow as they host your cannabis plants, consequently taking the lion’s share of your initial investment.

Having a good sense of what grow shelves are, their components, and how they function should put you on the roadmap to a profitable grow operation.

Indoor cannabis farming is cultivating plants entirely indoors, such as in a warehouse or skyscraper within a controlled environment.

There are two main components of indoor cannabis cultivation; vertical growing systems and controlled environment agriculture technology (CEA).

What Is Controlled Environment Agriculture Technology(CEA)

CEA is a technology-based approach to food production.

The aim is to provide protection to plants against harsh weather, facilitating an all-year growing season.

Moreover, it helps reduce pest and disease infection, enhance sustainability, increase yields, improve efficiency and save on costs.

CEA allows you to provide an outdoor environment indoors. The indoor environment automates your temperature, CO2, light, humidity, and nutrients for optimal plant growth and yields.

Some of the technologies used in CEA include hydroponics, aquaponics, and aeroponics.

Hydroponics is a standard technology in indoor grow cannabis cultivation. It’s a type of horticulture that involves growing your cannabis plants on hydroponic trays using water-based mineral nutrient solutions.

What Are Cannabis Vertical Growing Systems?

Vertical farming is cultivating cannabis in vertically stacked layers, also known as grow shelves.

The grow shelves carry your plants, lighting, ventilation, and irrigation equipment, ensuring your plants get the right conditions for growth.

There are a variety of vertical growing systems, such as vertical grow racks, mobile carriages, and tabletop caster units.

Each vertical growing system provides unique functionalities to help optimize your grow space.

But why emphasize vertical grow systems compared to traditionally used horizontal grow beds or tables for your indoor grow space?

Benefits of Vertical Growing Systems

1. Better Use of Indoor Grow Space

Stacked grow shelves allow you to expand upwards on your indoor grow space. Therefore you can achieve higher productivity on a small land area.

Moreover, mobile carriages can eradicate static aisles, saving more space. You only need to create aisles when catering to particular grow shelves in your grow space.

2. Vertical Growing Systems Minimises Water Usage

Cultivation on grow shelves is mainly done on hydroponic trays (or hydroponics technology). This technology uses up to 90% less water than traditional methods. As a result, fewer fertilizers and nutrients are used.

The water is also easily recycled and reused, reducing waste and lowering utility costs.

3. Safe Food Production

The cannabis plants are within a closed, controlled environment, so the infestation of pests and diseases minimizes.

For example, Indica strains are susceptible to mold attack within high humidity. Controlled humidity levels ensure optimum conditions for healthy plant growth.

Minimized attack of plants leads to little or no use of chemicals and pesticides and, thus, safe, high-quality plants.

Consistent Quality and Crop Production

Vertical growing systems present you with an opportunity to grow year-round. Moreover, with controlled environmental conditions, you can grow continuously without compromising quality or flavor.

Then again, with unique light frequencies and other customized growing conditions, you can enhance the flavor of cannabis plants, increasing your profit margins.

To reap these benefits, you must acquire suitable vertical growing systems that optimize your indoor space.

What to Look for When Choosing Vertical Grow Systems

- Size of Grow Space

Whether growing in a skyscraper, warehouse, container, or a simple home grow, there’s an ideal vertical grow system for your space.

For a home-grow, tabletop caster units provide the convenience and compatibility you need for a small space.

On the other hand, mobile carriages provide you with good space utilization and dependability for warehouse (or commercial) grow.

- Type of Plants

When deciding on the vertical system to purchase, you need to be conversant with the various cannabis strains.

For example, Sativas stains are a tall variety and hence can limit the number of tiers on your grow shelves. Conversely, Indicas are a short strain; hence, you may increase tiers depending on your space and plant more per square foot. It’s a similar case for hybrid strains. Each variety will provide its unique challenges.

Read more on Indica vs. Sativa vs. Hybrids on our blog for insights into their unique cultivation requirements.

- Lighting, Irrigation, and Ventilation Equipment

Some vertical grow racks have in-built lighting, but in most cases, they are built with provisions to install your grow lights.

Moreover, the tops of your tiers should be fitted with trays to accommodate your growing media. Be it soil, hydroponics, or aeroponics, vertical grow systems should be made to sustain your cultivation method.

Types of Vertical Growing Systems

Vertical Grow Racks

Vertical grow racks are made similarly to shelves you see in Costco or Home Depot. They are high-density steel structures that can support heavy weights.

The same structures were rethought and made for the indoor cannabis growing industry. That is considering the plant’s height, space for lighting, and other growing equipment to ensure healthy plants.

At MMI Agriculture, we have honed in on the farmer’s needs in cultivating cannabis and designed our vertical grow racks with utility and efficiency in mind.

Some common features include

- 14 gauge steel beams with interlocking tabs to ensure a tight fit

- Powder coated for rust resistance and maintaining cleanliness

- Provisions for installing grow lights and irrigation systems

- 3 feet wide shelving to ensure ease of access to plants

- Customizable vertical space for plants to ensure proper spacing between lights and canopy

- Ten years warranty on parts and labor

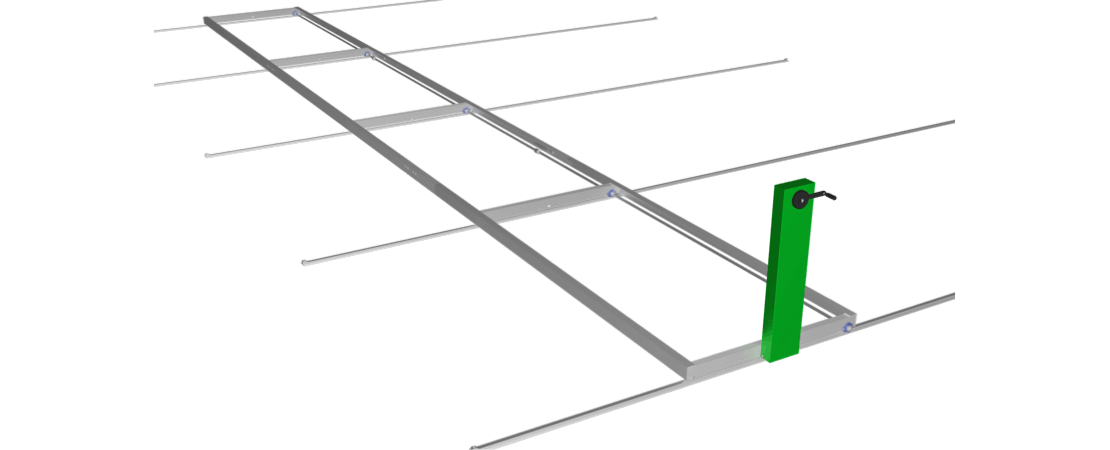

Mobile Carriages

Mobile carriages are multi-tier racks you can quickly move using a handle, even when loaded with cannabis plants.

It allow you to maximize further on your grow space by eliminating static aisles. You can create aisles and tend to your plants using the handle systems.

Notably, they are expensive compared to other vertical growing systems but are well worth the investment for commercial cannabis cultivation.

Some exceptional features of our mobile carriages include:

- Track capabilities and components

- Carriage capabilities and components holding up to 1400 pounds per carriage foot

- Drives and handles capabilities that include rust-resistant drive shafts and a standard single-spoke mechanical assist handle to help you move loads seamlessly and effortlessly

Tabletop Caster Units

For a home grow or mid-sized cannabis grow op, tabletop caster units are the ideal vertical growing systems.

These mid-sized indoor growing systems sit on caster wheels, making it easy to move between rooms. Additionally, the caster wheels are designed to swivel and lock in place.

Moreover, they are pocket-friendly systems to get you started on your indoor cannabis grow.

Moreover, for a commercial grow, the caster units are ideal for growing your seeds or clones, as you can seamlessly move them from the allocated growing sections to your vertical grow racks.

Get Reliable Vertical Growing Systems With MMI Agriculture

Choosing the proper grow shelves is pivotal to a successful cannabis indoor grow operation. They account for the biggest share of your initial investments, so you should ensure you get it right the first time.

MMI Agriculture is an indoor growing systems installation company with years of experience in the industry. Our high-density uprights and personalized preliminary services, like capacity evaluations and free floor plan drawings, ensure a seamless shift into vertical farming.

We set you up and provide a 10-year warranty on our installation services and equipment, ensuring you get settled into this lucrative industry.

So, what are you holding out for? Contact us today for a quote.