How Does Vertical Farming Work? Learn Why Up Is The Way To Go

How does vertical farming work? Is it any beneficial?

The most significant challenge to an indoor farming enterprise is space. The growing demand for cannabis products necessitates expansion. More room, like a domino effect, means expensive real estate leasing, higher utility, labor costs, as well as a plethora of other potential obstacles.

Vertical farming may hold the secret to limiting the growing expenses of expansion by maximizing space. This farming strategy allows you to maximize space without sacrificing quality or productivity.

Cannabis farming has seen slow technological progress, though it basically pioneered sunless cultivation. However, vertical growing companies are at the forefront of revolutionizing the industry.

What Is Vertical Farming?

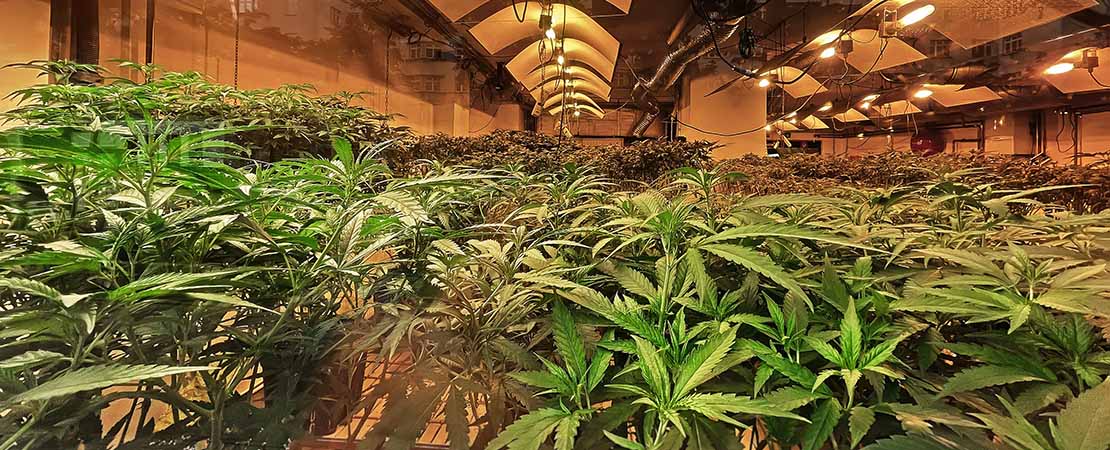

Vertical farming is the production of crops on vertically stacked tiers.

The plants are cultivated on vertically stacked layers and fitted into structures like a refurbished warehouse.

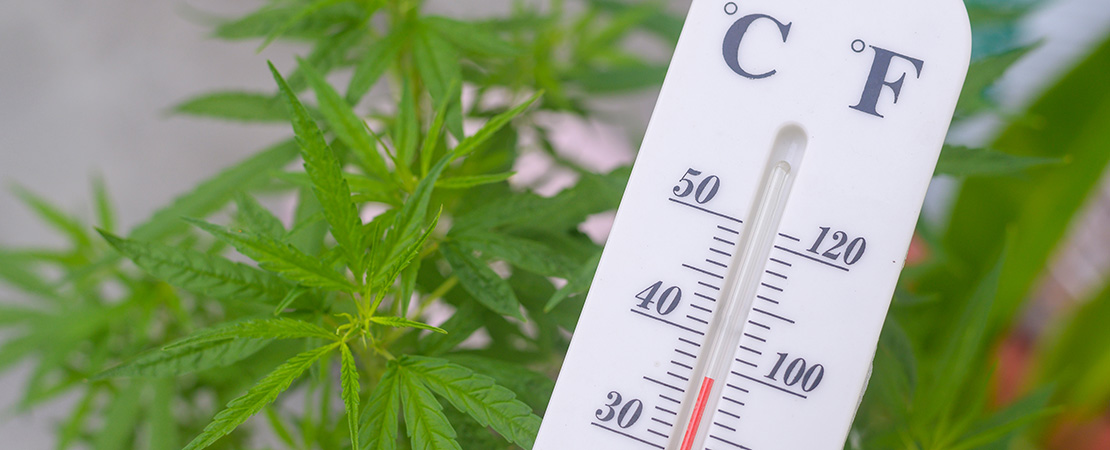

The method utilizes controlled environment agriculture technology (CEA) which employs indoor farming techniques. CEA involves the artificial control of temperature, humidity, and light.

The primary aim of vertical farming is to maximize crop yields in a limited space.

There are two main types of marijuana vertical cannabis farming.

1. Stacked Vertical

Stacked vertical is a common method where multiple racks are stacked on top of each other around a central light or with lights on each shelf. The setup allows you to use the space between the floor and roof, maximizing space.

The plants need to be kept short and bud heavy when using the system. Hydroponics and soil-based vertical grow systems are suitable for this approach.

2. True Vertical

True vertical is the advancement of the stacked method. The stacked model is more or less 2-3 horizontal farms built on top of each other.

In true vertical growing, plants grow out the side of a column; nutrients and water are drip-fed to the plants from the top.

The method utilizes aeroponics and the nutrient film technique (NFT), which entails the direct application of nutrient water to roots.

How Does Vertical Farming Work? 4 Important Factors To Consider When Setting Up Indoor Vertical Grows

The following 4 factors are critical to the process of vertical farming.

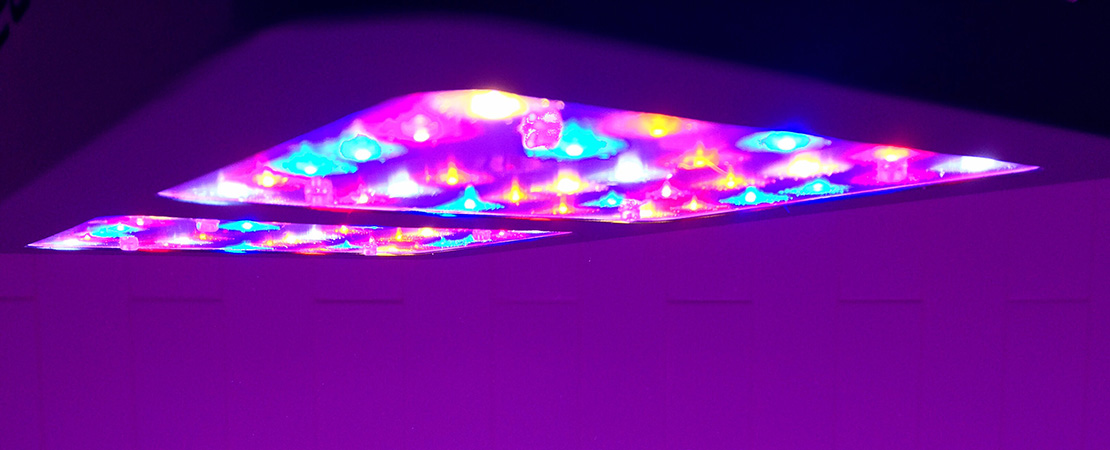

1. Lighting

Since most vertical farms are built indoors, it’s critical to keep an eye on the amount of light in the area. Farmers can use natural lighting, artificial lighting, or a combination of the two.

Artificial lights play a significant role in achieving the proper light balance for your plants. Cannabis plants, for example, require 18 hours of light during the vegetative stage and 12 hours during the flowering stage. It’s impossible to rely on natural lighting to maintain each plant stage. Fortunately, automated lighting can assist in creating the ideal conditions.

2. Physical Layout

The physical layout entails designing your grow room. Vertical farming involves stacking plants vertically. Therefore, you have to consider tower-like structures in your design. These structures could bring a different dynamic when allocating positions for associated equipment like air conditioners, dehumidifiers, lamps, etc.

3. Growing Medium

A grow medium is anything that allows plant roots to develop and take water and nutrients. The grow media you use significantly influences the quality of your plants. Aeroponics, aquaponics, hydroponics, and soil are viable growing medium solutions.

In addition, there are other unconventional organic materials used in vertical farming, like coconut husks and peat moss.

4. Sustainability

The major advantage of vertical farming is the maximization of available agricultural space, increasing the output of existing resources.

In addition, vertical farms are more efficient than traditional methods because they use only 5% of the water.

Six Reasons Why You May Want To Switch To Vertical Farming

1. Less Water And Space

When compared to traditional farming, vertical farming uses 70 – 95% less water to produce crops. This is owing to the advancements made in vertical farming design.

Additionally, there are more freshwater savings when farming on a large scale, impacting overall production costs.

2. Increased All-Year-Round Production

Vertical farms allow more crops to be grown in the same amount of space. According to a Columbia University report, 1 acre of indoor space is equivalent to 4 – 6 acres of outdoor space.

CEA technology’s controlled indoor environment allows for plant production all year in summer or winter. All the necessary conditions are present in the grow room for cannabis growth.

3. Eliminates Environmental Impacts

Flooding, drought, and severe rainfall can be devastating to crops grown outdoors. Furthermore, these conditions are becoming more common and severe due to global warming.

On the other hand, indoor vertical farms remain sheltered from the elements, assuring a plentiful harvest regardless of the season or weather.

4. Increase In Organic Hemp Production

The hemp is grown in a controlled environment, eliminating the need for chemical pesticides or herbicides.

5. Preparation For Urban Migration

Vertical farms are viable for cultivating cannabis in urban locations where space is limited and demand is high.

6. Environmental Friendly

Animals or vegetation in the wild remains undisturbed, encouraging biodiversity.

Likewise, workers remain safe from work hazards experienced with typical farming like heavy machine-related injuries and exposure to harmful chemicals.

Three Main Challenges Facing Vertical Indoor Cannabis Farming

1. High Initial Investment

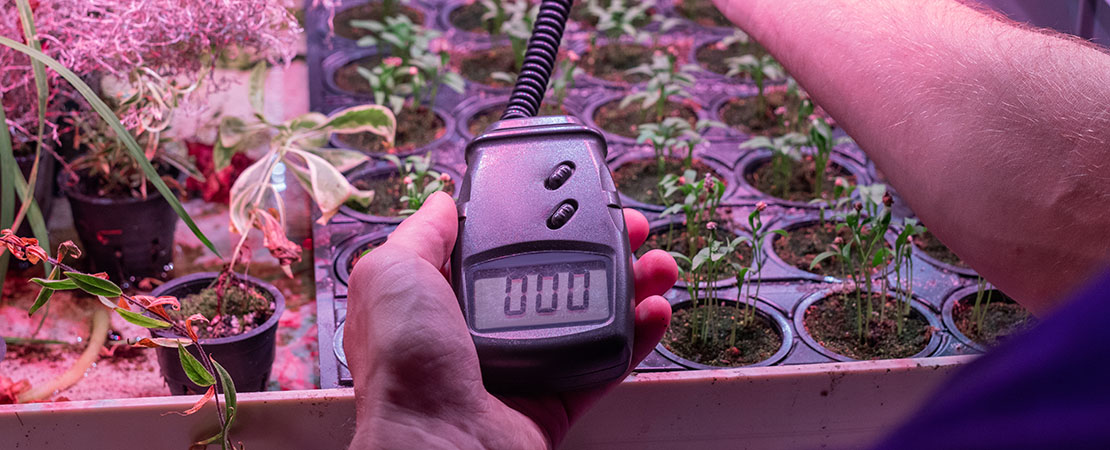

Overall, vertical cannabis farming is great value as you can grow more cannabis in a smaller horizontal space. However, buying quality equipment can raise the cost. Also, acquiring skilled labor and purchasing associated equipment for climate control and additional equipment like ladders and sensors can drive up the cost.

2. Safety And Compliance Issues

As the racks go up, new hazards emerge, as technicians might need scaffolding or ladders to tend the plants. In such cases, you need to comply with OSHA regulations which can be restrictive for monitoring the structural stability of mobile racking systems exceeding two tiers.

3. Climate Control

Maintaining the ideal temperature, humidity, and air circulation in vertical farms can be difficult since the number of factors to monitor grows with stacking.

Microclimates develop, raising the challenge of keeping the same conditions at the top and bottom of the vertical systems with increased plants.

The situation will demand advanced climate control systems for every cubic foot to preserve the weed.

Four Quick Steps On How To Start Vertical Cannabis Farming

1. Choose Your Vertical Grow System

Quality should guide your decision when choosing a vertical racking system. You should consider irrigation pressure, drainage, electricals, and the plant’s actual weight. A sturdy vertical rack with cross and diagonal beams keep your plants secure and your workers safe.

It’s also vital to have the option of customizable racks in order to have something that fits your available space. Another consideration is whether you need stationary or mobile racks.

Mobile racks ensure that you are maximizing your grow space and utilizing every inch of your operation. Stationary racks, while they do require more space due to the need for more aisles, are an affordable alternative to mobile racks.

MMI Agriculture offers the most robust customizable uprights on the market, which are available in our online store.

2. Select Your Grow Lights

There are various grow lights available such as LED and HIDs grow lights.

Each type has its advantages and disadvantages; for example, LEDs are costly yet have low power usage. HIDs are less expensive, but they generate too much heat.

The type of product you strive to grow determines the light to use. For most marijuana plants, broad-spectrum is sufficient. Pink light helps develop exotic buds as it gives you control over the quality of buds.

3. Automate Your Environmental Controls

There are many pieces of equipment used to ensure good climate control. Vertical systems can make your grow room dense, introducing microclimates in your grow room. To solve this, invest in sensors to automate your climate control equipment.

For good airflow, push the fresh air down the open spaces of your racking system and pull it out the other end.

4. Pick A Production Method

Space is limited in vertical grow systems; hence, you need to limit the plant height. Your plants should grow to a maximum height of 4 feet and remain in the vegetative stage for a short time.

Going vertical also means you’re doubling or tripling your previous yield.

With the short plant cycle and increased output, you must rethink your strategy. You are transforming into a manufacturing facility where your goods have to move quickly.

Tips For Growing Cannabis Vertically

There are several aspects to check before purchasing vertical equipment.

- How the grow racks fit, ensuring good workflow and maximum space utilization.

- Proper light spacing and distance from the canopy are good for adequate light coverage

- Proper sanitization procedures and surface material to prevent contaminants.

- If a beginner, start with two tiers stacking systems.

- Understand the microclimate within your grow space for better climate control.

- Choose the proper strain. Short cannabis strains are preferred.

- Plan out your grow room. Your workers need adequate space to tend to the plants higher up, which necessitates ladders or scaffolding. There should also be room to remove trays for cleaning or replacement.

- Clean your pipes regularly and manage wastewater.

Ready To Make The Switch?

Vertical farming systems are the way to go to make the most of your grow space. MMI Agriculture offers high-quality racking that is backed by an industry-leading 10-year warranty to ensure that your operation runs smoothly for years to come.

Contact us now to revamp your space for higher yields.