9 Essential Vertical Farming Equipment That You Should Know

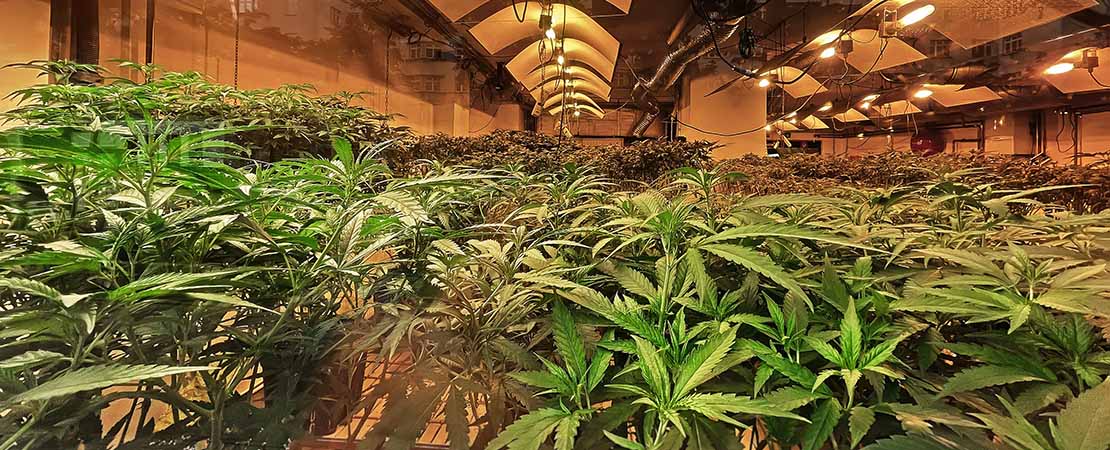

Vertical farming is exponentially replacing the traditional way of growing cannabis today. According to Grand View Research, the global vertical farming market is expected to grow by 25.7% by 2027.

There is huge potential in the vertical farming market for cannabis and the need to transition into vertical agriculture arises if you plan on scaling your cannabis business.

With more and more states going forward with the legalisation of cannabis, there is even more incentive to utilize vertical farming. In the future, there could be more demand for cannabis than the supply chain can meet.

Therefore, adopting the vertical cannabis farming approach breaks the aforementioned barrier, as you would have the opportunity to increase your growing capacity, which in turn improves your yields.

Are you a cannabis farmer growing indoors, and looking to maximize your space and yields? Look no further!

This article is aimed to demystify your understanding of vertical farming for cannabis, the associated technology, and the equipment required to maximally reap from vertical farming benefits.

What’s Vertical Cannabis Farming?

Vertical cannabis farming is a sustainable system of cultivating cannabis, together with other types of fruits, flowers, and vegetables. It uses nearly 100 percent less space, up to 95 percent less water, and harvesting 80 percent more per unit area, year-round when compared to the traditional cannabis growing methods.

With vertical growing systems, you’re not only optimizing your canopy space but also reducing your labor costs and growing time through automation and standardization.

Moreover, it also serves as a suitable alternative to the costly real estate for large-scale cannabis-producing farmers.

Vertical cannabis farms exist in unique shapes and sizes, from shipping containers to abandoned buildings, and employ one of the three soil-free systems to provide growth nutrients to plants: hydroponic, aeroponics, or aquaponics – owing to their potency, eco-sustainability, and economic benefits.

What’re the Merits of Vertical Cannabis Farming?

Vertical farming companies have been on the rise today owing to the merits vertical cannabis growing affords.

The advantages include:

- Helps to optimize and maximize production capacity within a limited growing space.

- Provides the avenue to grow other consumable plants along with it.

- Allows for efficient use of utilities, through LED lighting, and closed-loop irrigation systems that capture and reuse water.

- Provides a sustainable cultivation platform for multi-state operations to streamline, standardize, and improve outputs.

- Eliminates the need to acquire another growing space as the demand increases, by maximizing the existing space available.

- Enhance employee safety and ergonomics through platforms and lifts that harmonize to optimal work height.

- Increases horizontal canopy space via elimination of stationery aisles, by developing a more vibrant growing space.

- Helps to improve efficiency and return on investment (ROI).

What is The Technology Employed in Vertical Cannabis Farming?

Vertical cannabis farming integrates a variety of state-of-the-art technologies, including mobile vertical grow racks, specialized LED lights, and air-flow systems. More often than not, they are combined into fully integrated systems.

Understanding Essential Equipment for Vertical Cannabis Farming

With the upsurge in the competitive cannabis market, maximizing your efficiency and return on investment (ROI) should be your competitive advantage. Identifying and choosing the necessary vertical farming equipment is the beginning of your success.

Below are vertical farming equipment needed for successful vertical cannabis growing:

1. Vertical Grow Racks

The skeleton of every vertical farm is a mobile vertical grow rack system. It’s the most effective and essential solution to successful vertical farming.

MMI Agriculture’s vertical grow racks help you expand your available grow space horizontally, presenting you with more than enough spaces and multiple levels for your cannabis farming.

Our uprights are available up to 21′ high, allowing for dual-level access. We have the ability to go higher upon customer request. We utilize cross and diagonal beams resulting in one of the strongest uprights on the market.

Our bulk racking is made of 14-gauge steel with an 8-bend design for extra strength. Our step beams are also 14-gauge steel with three interlocking tabs per upright for additional rigidity.

Using our vertical grow racks not only affords you the opportunity to optimize your unused spaces and boost your overall yield, but also offers you vertical grow racks that have maximum strength and durability in a high-humidity environment.

2. Mobile Carriages

While it’s important to choose the right racks, it is also essential to choose and correctly install the mobile carriages the racking sits on. While the grow racks function as the skeleton, the mobile carriages are the muscles, providing locomotion to the bones (the grow racks).

MMI Agriculture’s mobile carriages are manufactured in-house, giving us the competitive advantage to design and customize every system to serve each unique grow operation.

Our carriages can extend up to 56 feet, sit atop flange wheels with the capacity of supporting nearly 1,400 pounds per linear square foot.

Be informed that the right mobile carriages must conform to ADA compliance standards. They need to ensure worker safety and should be corrosion and oxidation-resistant.

At MMI Agriculture, we can get you covered and help you with customized mobile carriages with the aforementioned standards hassle-free.

3. Grow Trays

Once the vertical grow racks are built, the next is to fill them with grow trays. Grow trays provide bedding from which your cannabis plant grows, enjoy lighting, air circulation, and plumbing.

An acceptable grow tray must be durable, with UV stability, anti-microbial, anti-fungal, and have a built-in trough that facilitates easy drainage to ensure a sanitary vertical growing environment.

4. LED Lights

Vertical farming employs the use of LED lights on each growing tier. Lighting, in addition to air and water, provides cannabis with the necessities required to grow healthy, vigorously, and yield higher concentrations of cannabinoids, flavonoids, terpenes, and other active compounds.

When selecting LED Lights for your vertical cannabis farm, ensure the spectrum, intensity, and layouts fits your need, commonly between 750 and 1500 PPFD.

The lights must be rated IP65 or IP66 for wet environments, must be easily dimmable, and with the capacity of delivering an even distribution of PPFD across the entire rack.

4. Air Flow System

Vertical farming requires unique air circulation. This is attributed to the restrictions and obstructions caused by infrastructure and the multiple tiers of cultivation. As a result, microclimates might form.

Ensuring sufficient airflow and fresh air exchanges are indispensable to cannabis health, as they help in controlling pests and pathogens throughout your entire facility.

5. HVAC System

The HVAC system provides entry for fresh air and allows exit for used air via the ventilation system. It ensures the air is clean, circulating, and well-regulated within the minimum temperature and humidity that support your cannabis growth.

When selecting an HVAC system, it’s crucial to select one that facilitates adequate cooling and heating loads specific to your production plan. Dehumidification needs and irrigation rates are necessary features to also consider.

Furthermore, your HVAC system should always be clean and sanitary, as it allows for normal, fresh-treated air exchange and eliminates the growth of mildew, mold, bacteria, and other air pathogens around your vertical farm.

6. Irrigation and Fertigation Systems

Some vertical cannabis companies are known to provide irrigation and fertigation systems and controls to commercial cannabis farmers worldwide.

It’s an automated irrigation system that facilitates efficiency, reduces water consumption, and eliminates costly and strenuous labor frequently linked with hand watering and manual fertilizing.

7. Grow Sensor and Monitors

Grow sensors and monitors are one of the high-tech, data-driven evolutions in cannabis growing today.

These tools permit you to have a macro and micro view of your entire cannabis grow operation, with in-depth analytics such as the air temperature, humidity, VPD, soil temperature, pH, lighting, and substrate moisture, etc.

Open API and integration with other systems and controls are what you should consider when purchasing grow sensors and monitors for your vertical cannabis farming.

8. Mobile Carts

Since you have optimized the cultivation aspect of cannabis growing, extending such to processing and drying is also a no-brainer. There are mobile drying, storing, and transportation carts that help to ease workflow on your cannabis farm.

When opting for a mobile drying cart, confirm its durability, flexibility, and hanging options (such as cantilever-style finger attachments).

Security cages, nesting bases, antimicrobial and antifungal coatings are some other features you should check.

9. Storage Lockers

Investing in high-quality storage lockers assures your employees that their belongings are safe.

Remember without their helping hands, you may have difficulty going a long way even when your farming operations are automated.

Ready to Shift to Vertical Cannabis Farming? Partner with MMI Agriculture Today!

At MMI Agriculture, we offer affordable/accessible pricing, a 10-year warranty on parts and labor (one of its kind in the industry), and free design services to all our clients to ascertain you are optimizing your available grow space.

Features and benefits of our products include:

- Our mobile systems can help you double or triple your expected yields.

- Nationwide installation services to ensure every system is installed and operated properly.

- Easy integration with all types of lighting.

- We offer a retractable mezzanine walkway that facilitates easy access to crops on high elevations.

- We also offer tabletop caster units that are a little more restricted for space and don’t necessarily require a large-scale mobile cultivation system.

Presently, we provide services within the states that have legalized cannabis medicinally or recreationally or both, including Alaska, Arizona, California, Colorado, Washington D.C., Illinois, Maine, Massachusetts, Michigan, Montana, Nevada, New Jersey, New York, Oregon, South Dakota, Vermont, Virginia, and Washington.

Ready to grow and save more? Trust us with your grow operation by learning more and/or getting a quote now!