How a Commercial Grow Operation Cures Cannabis for the Best Results

Optimizing your cannabis grow operation doesn’t just stop at installing a state-of-the-art cannabis indoor grow system.

After exponentially increasing your cannabis harvest thanks to vertical growing racks, properly drying and curing cannabis will lead to a superior cannabis product that will pull you ahead of the competition.

When cannabis is properly dried and cured, the process leads to an accentuation of flavors thanks to the preservation of terpenes and cannabinoids.

That’s not all. Drying and curing cannabis will also lead to a generally improved smoking experience thanks to the eliminated chlorophyll, which makes buds burn unevenly and taste too green.

But before getting into the meat and bones of drying and curing cannabis, it’s great to clear out confusing terms immediately.

Though curing cannabis and drying cannabis are used interchangeably by cannabis growers of all levels, they refer to very distinct processes.

After cannabis has undergone a drying process to remove most of its moisture, it then undergoes a curing process to help it stay fresh for longer while preserving its moisture, flavors, and potency.

In this article, we take a closer look at curing cannabis to discover all the process that goes into it, including the initial drying stage.

We’ll dive into the step-by-step process of cannabis curing and highlight the temperature, humidity, and light requirements to cure cannabis correctly.

Drying Cannabis

Drying cannabis involves removing about 75% of the plant’s moisture content. The process consists of putting cannabis in an environmentally controlled room for about two to seven days.

Methods of Drying Cannabis

Before cannabis is dried, it undergoes an initial process that involves removing large fan leaves.

In your dry room, you can either choose to hang dry cannabis or spread it out on a flat rack.

Hang Method

The hanging method involves hanging the whole cannabis plant or large branches on a line or hanger.

After two days, you can perform a dry test by bending a cannabis branch. A snap would mean the plant is adequately dry.

Once the cannabis is adequately dry, dry trimming separates unwanted plant material from the cannabis.

Some cannabis growers prefer the hang drying method as it prevents deformation and flattening of buds during the drying process.

It’s important to note that this method will mean your cannabis plant will take longer to dry due to the presence of more vegetative material.

Also, since the hanging method involves trimming the plant after it dries, it would mean more space is needed.

Flat Rack Method

Choosing to wet-trim your buds will mean less plant matter, less drying space, and less drying time.

With many trimmed individual buds, the most convenient way to dry them would be on a flat rack.

Such racks are made of mesh, and they have multiple vertical layers. The mesh allows for excellent airflow, while the vertical layers will enable you to stack more trimmed buds and save up on space.

The dry test on the trimmed buds will be a bit different. After two or three days, gently squeeze the bud. If it’s too wet, it needs more time to dry.

How to Set up a Drying Room for Perfectly Drying Cannabis

Whether you prefer to rack dry or hang dry your cannabis, you’ll need to set the plant up in a room optimized for drying.

For the best result, you’ll need to optimize the temperature, humidity, and light in the room.

It would be best to work with a small room exclusively dedicated to drying as it can be hard to control the humidity and temperature of a big room.

Cannabis Drying Room Equipment

- Hygrometer to measure temperature and humidity

- Fan

- AC (optional)

- Dehumidifier (optional)

- Tabletop caster units

Cannabis Drying Conditions

A good drying room will need a humidity range of 55-65% and a temperature range of 60-70°F. A hygrometer can come in handy to help you monitor both these values.

You can use a dehumidifier or an AC to lower humidity as needed.

A small fan at low speed is excellent for ensuring continuous air circulation.

To speed up the drying process, you can drop the humidity to 50% and increase the temperature to 75°F.

You can choose to have your drying room dark or use LEDs or green fluorescent lights for light requirements. UV light can degrade cannabinoids and terpenes in cannabis.

Moreover, with our tabletop caster units you can hang or flat dry your cannabis plants with ease. The vertical system gives you both mobility and added capacity to dry your plants.

Curing Cannabis

As mentioned earlier, the aim of drying is not to eliminate all the moisture content from cannabis.

After the initial drying process, cannabis will appear dry outside but some moisture will still be retained within the bud.

The curing process aims at redistributing and locking moisture throughout the bud to preserve aromatic flavors and potency.

The process takes two weeks to one month and involves sealing cannabis in an airtight container at a humidity of 55 to 65% and temperatures of 64°F – 70°F.

Importance of Curing Weed

As cannabis cures, moisture continuously moves from the center to the outside of the buds. Also, chlorophyll continues to break down, removing the vegetable taste of cannabis.

Additionally, the process preserves the smell, flavor, and potency of the cannabis buds as Terpenes—which are aromatic compounds—are sensitive and quickly degrade if the proper curing measure is not taken.

Curing cannabis increases its life span exponentially, preventing molding, potency, and flavor loss.

Equipment You Need to Cure Cannabis

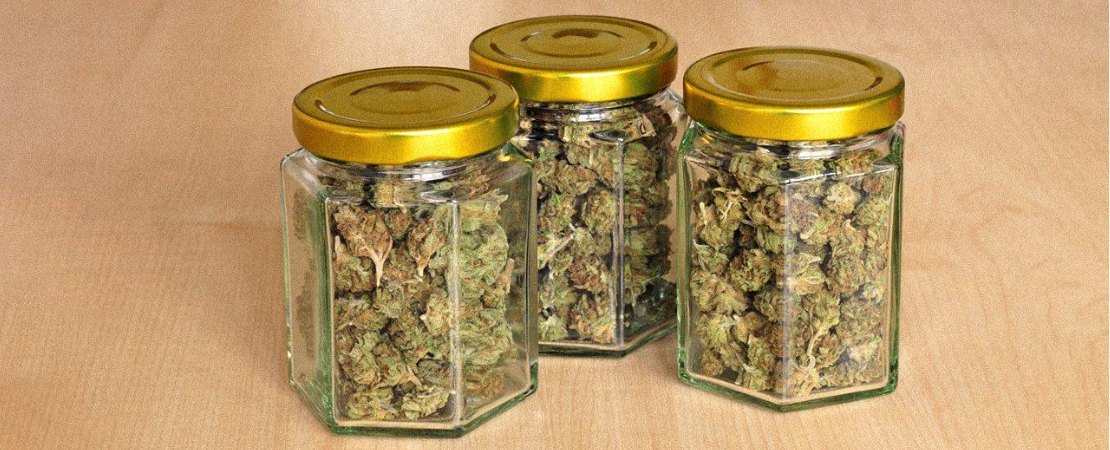

- Airtight jars

- Hygrometer

- Humidification pods

Glass, ceramic, metal, and wood vessels are ideal. On the other hand, plastic bags and containers are unsuitable as they will affect the taste of the cannabis and allow in oxygen.

Ideally, each container needs a hygrometer to measure the ideal conditions. A humidification pod can come in handy to ensure that the perfect humidity is met in each container.

The Step-By-Step Process of Curing Cannabis

Curing Cannabis Step 1: Pack Your Buds in an Airtight Container.

You must pack the buds loosely and avoid compacting the container to allow for proper airflow when needed.

The airtight container should then be stored in a cool dark place away from direct sunlight.

After two days, the buds will become soft as moisture rehydrates them.

If this doesn’t happen, it means you overdried your buds during the drying stage. To solve this, add a humidification pod to the container to add more moisture to the buds.

If the buds did not dry adequately and appear wet before the curing begins, leave the container lid open for 24 hours so the buds can dry up a bit.

Curing Cannabis Step 2: Burp Your Buds.

During the next week of the curing process, you’ll need to burp your buds once or twice daily. Burping involves opening the sealed cannabis container for a few minutes to allow oxygen and release moisture.

After the first week, you can reduce the frequency of burping to twice or thrice a week.

When burping, if you notice an unpleasant ammonia odor, it means bacteria are consuming the buds. This can lead to the rotting of the cannabis and mold formation. To avoid this, leave the lid open for 24 hours.

Curing Cannabis Step 3: Wait for the Buds to Cure

After two to four weeks, your cannabis should be appropriately cured to preserve all the flavors, potency, and aromas. Properly cured buds can stay optimal for up to two years if stored correctly.

Curing Cannabis Step 4: Properly Store Your Buds

The ideal storage location for your cured buds should be a cool dark place free from moisture and oxygen.

A vacuum-sealed glass jar should work fine. A hygrometer can help you monitor temperature and humidity, while a humidification pod can enable you to control humidity in the storage container.

Importance of Maintaining Optimal Conditions During Storage

- Light

Even though short-term exposure to UV light won’t significantly affect the quality of your cannabis, long-term exposure will lead to the gradual degradation of cannabinoids and terpenes in the cannabis plant.

- Humidity

The ideal humidity for storing cannabis is 55-65% relative humidity. Higher humidity levels will encourage the growth of mold and mildew, while lower humidity will lead to the degradation of essential plant materials.

- Temperature

The high temperature will lead to the breakdown of a critical cannabinoid called THCA.

Continuous exposure to high temperatures will cause THCA to break down into THC and CBN. CBN is a non-psychoactive cannabinoid that can cause tiredness and headaches when smoked.

Elevate Your Commercial Grow Op Utilizing Indoor Growing Systems

For a commercial cannabis farmer looking to expand your business and double or triple your income, an innovative solution like a cannabis vertical growing system will suit your business needs.

At MMI Agriculture, we specialize in installing cannabis vertical grow systems such as our versatile vertical grow racks and mobile carriages. No matter your indoor space, we have a team of specialists who will customize floor plans to maximize your grow space.

We also have an installation team all over America to ensure your systems are fitted flawlessly and running smoothly.

Both our labor and equipment come with a ten years warranty to guarantee reliable quality when you choose to work with us.

Want to learn more about our commercial indoor growing systems? Contact us today.