The Vertical Grow Shelf System Checklist For Growing Cannabis Indoors

We live in a rapidly urbanizing world, which necessitates the agricultural sector to develop innovative solutions, such as a vertical grow shelf system, to supply fresh produce in urban areas.

With high pollution levels and the resulting inhospitable conditions for crop cultivation, arable land is becoming scarce.

Industries and Agtech are leading research into indoor crop cultivation. The practice is commonly known as Indoor farming or precision agriculture.

Indoor farming entails creating artificial conditions for plant growth that mimic outdoor conditions.

This agricultural method is also known as precision agriculture because it uses AI and automation to allow farmers to grow crops to a specific taste and quality.

At the core of indoor farming are vertical grow shelf systems. These are vertical systems that help maximize land use per square foot by helping you grow vertically.

What Is a Vertical Grow Shelf System

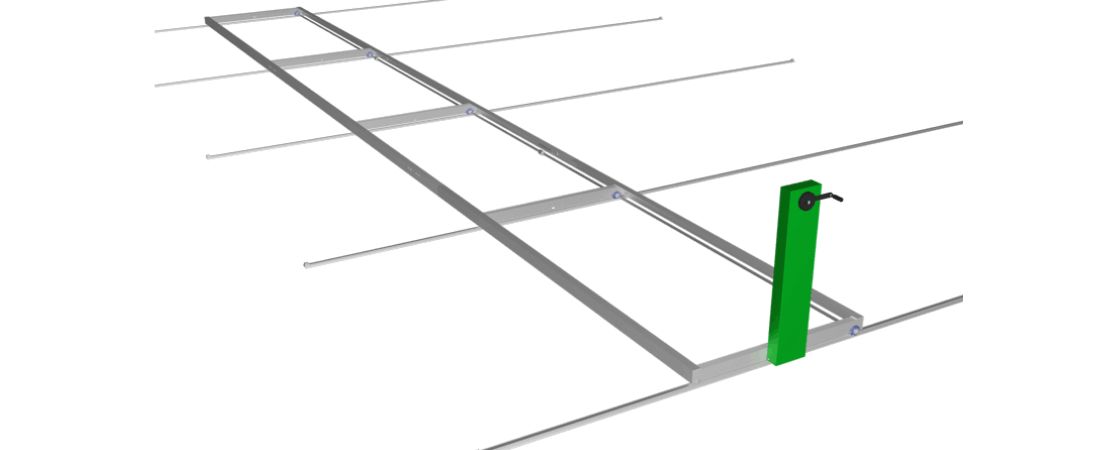

A vertical grow shelf system is a multiple rack system you can use to cultivate your cannabis plants.

These systems come in various designs in terms of materials and accessories.

For example, a light-duty tabletop caster unit comes with caster wheels for easy mobility between rooms. On the other hand, we have heavy-duty mobile carriages that have a lever system to move loads of crops within a given grow space.

Then again, we have materials used in the construction of a vertical grow shelf system.

High-quality systems are manufactured with steel to give them rigidity and curtail the spread of pests and diseases. Steel is also a material that is easy to clean and can withstand the moist conditions of a commercial indoor grow room.

5 Advantages of a Vertical Grow Shelf System

Increase Production Capacity

A vertical grow shelf system helps farmers grow crops all year round. Because indoor cannabis farming is not dependent on outdoor conditions, you can grow in any season, whether winter, summer, or spring.

Moreover, with the year-round cultivation, the increased tiers can allow you to run like a manufacturing facility due to increased and consistent yields.

Maximize Vertical and Horizontal Grow Space

Vertical growing systems not only help increase vertical grow space but also horizontal space.

For example, mobile carriages help eliminate static aisles. These vertical grow racks are mounted on a carriage system, which allows you to move the shelving systems side to side and hence you can create aisles when necessary.

Easy to Integrate Conditioning Equipment

The cannabis vertical growing systems need to be sturdy to carry both the weight of crops and environmental conditioning equipment. The vertical grow racks need to carry the irrigation systems and lighting systems.

Moreover to help overcome the formation of microclimates they may need to carry some light-duty HVAC equipment. Most vertical grow shelf systems are made to integrate with conditioning and lighting equipment from most companies.

Reduce Energy Costs

Vertical grow systems help you save on energy costs by having your powerful ACs run at optimal capacity for a given space. When compared to horizontal systems, one AC can serve more crops per square foot.

Moreover, by incorporating IoT sensors into your vertical farms you can regulate the environmental equipment and maintain optimum conditions.

Customizable to Any Grow Space

Vertical growing systems installation companies prepare floor drawings allowing them to create customized systems. The customized systems ensure your space is well utilized.

In addition, the systems can be customized to facilitate the cannabis variety you are growing to ensure high efficiency.

With customized vertical grow shelf systems, you can also compute the capacity evaluations for your space, hence you can better project the expected gains.

Top 5 Considerations For a Reliable Vertical Grow Shelf System

1. Durable Construction Material

Vertical growing racks are commonly made of steel. Steel is a material that offers, rigidity, durability, and ease of cleaning.

A vertical grow shelf system is an expensive purchase and so it has to be durable to ensure a good ROI.

In addition, the indoor growing environment needs to remain clean to ensure optimum conditions for plant growth.

Using steel on our mobile carriages means they can carry up to 1400 pounds per carriage foot. This can comfortably carry your crops, grow medium and lighting equipment.

You also need to consider the quality of grow trays. They have to be sturdy to hold up the weight of grow medium and crops planted.

Our grow trays are made to withstand temperature fluctuations and the wear of daily agricultural use. They also have rounded edges for easy cleaning and drain channels to ensure your crops aren’t waterlogged.

Remember to have the trays fit perfectly to your grow systems. Hence, it may be prudent to buy both your vertical systems and grow trays from the same installation company.

2. An Experienced Installation Company

It’s important to obtain your vertical grow shelf system from a reputable company.

A reputable company ensures a smooth transition into vertical farming with mitigated risks.

There are various perks to partnering with an experienced vertical systems installation company;

-

- Free floor plan drawings to ensure your grow space is optimized.

- Capacity evaluation which allows you to have a definite business plan

- Seismic calculations. The safety of your employees and operation is crucial. Vertical growing systems need to be designed and fortified to overcome seismic complications.

- Warranty on parts and labor. A good warranty from an installation company keeps you easy as you can identify the longevity of your vertical growing equipment. For example, at MMI Agriculture we offer a 10-year warranty on parts and labor to get you started and prosperous in your operation.

- Permit acquisition

When choosing a vertical growing systems installation company ensure they have the above features to support your vertical farming efforts.

3. Customization Support (For the Cannabis Variety)

Are you growing cannabis Sativa, Indica or Hybrid in your indoor vertical farm? Then you need to consider the different growing requirements for each of these cannabis strains.

In our article “Indoor Cannabis Growing: Cannabis Indica vs Sativa vs Hybrid” we’ve gone in-depth on what each strain demands.

However, there are a few key points you should consider right away when purchasing a vertical grow shelf system for each cannabis variety:

- Indica. It’s a short and bushy cannabis variety. Their stature can allow you to have more tiers. However, they have dense buds making them prone to diseases. Good ventilation is a must for high and quality yields.

- Sativa. They are a tall variety with a longer maturity cycle. They can lower the number of tiers and increase energy costs due to the long maturity cycle

- Hybrid. These varieties give you the best of both worlds. The dense buds and short growth cycle of the Indica and mold resistance of the Sativa. The dominant variety will influence the number of tiers you can install for your grow space.

4. Phased Vertical Grow Shelf System Installation

The advantage of having a vertical grow shelf system for your indoor cannabis operation is that you can install it in phases.

Notably, vertical farming is a capital-intensive venture.

With this in mind, you can devise a strategy for installing your indoor grow systems in sections/phases. In due time, you can add more systems hassle-free as there are floor plans to give direction and clarity on your project goals.

Furthermore, if you have a midsized operation you can leverage tabletop caster units to grow your crops.

5. Ergonomics

The vertical grow shelf systems platforms shouldn’t be too wide. They should make it easy for workers to tend to each plant.

The workers should have an easy time reaching for crops on top tiers. There’s an option for workers to use ladders. However, when harvesting, they may need to move loads of plant material and their safety can be a concern.

Fortunately, there’s innovations such as the retractable elevated decking you can assess using a scissor lift or ladder. The decking runs through the entire span of your vertical system, allowing your workers to save time and energy working on the top tiers.

Moreover, the mobile carriages are fitted with drive and handle capabilities allowing your workers to move loaded systems with one hand and access the crops.

Grow Higher With MMI Agriculture Vertical Grow Shelf Systems

At MMI Agriculture we specialize in vertical grow shelf systems installation.

Our expertise allows us to help support cannabis companies in their transition to vertical farming by supplying high-quality vertical systems all over the USA.

We partner in the success of your farm by providing 10 years warranty on parts and labor. Moreover, we have support services such as capacity evaluations and free floor plan drawings.

Ready to make the shift? Contact us today for a quote.