The Tested Way to Cultivate Cannabis Profits Using Indoor Vertical Farming

Here’s everything you need to know about how vertical farming can elevate your indoor cannabis commercial grow room.

As the world’s population grows, the supply of fruits and vegetables is falling 22% short of global nutritional needs. The expanding population outpaces the ability to feed itself, necessitating further innovation such as controlled environment agriculture (CEA) or vertical farming.

Modern cultivation problems include water shortage, land scarcity, and an ageing farming population. CEA is a solution working to address all of these issues and more.

Indoor commercial vertical growth has been found to boost crop yields by increasing arable space vertically per square foot and circumventing the land area limitation.

Humans have improved agricultural practices over time, and vertical farming is redefining urban agriculture to secure adequate, high-quality food for everybody.

What Is Indoor Vertical Farming In A Commercial Grow Room?

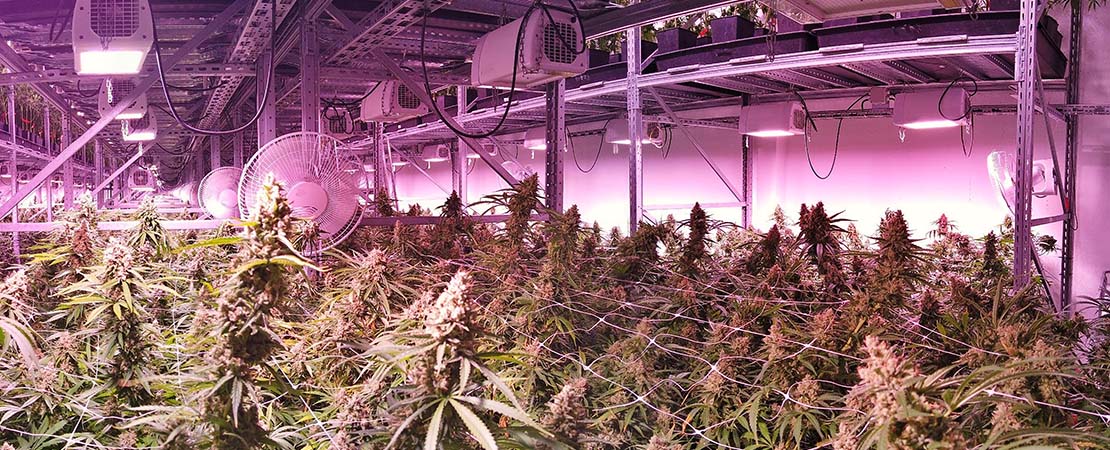

Vertical farming is growing crops vertically in stacked layers in a closed and controlled environment.

CEA controlled environment agriculture is a technology-based approach to food production that incorporates indoor agriculture and vertical farming. CEA protects crops from harsh external factors and ensures that they grow under ideal conditions throughout their life cycle.

Everything plants require at various phases of development is artificially provided in CEA or vertical farming. Your commercial grow room will need water, temperature, humidity levels, ventilation, lights, and CO2 available to your plants.

Indoor commercial cannabis cultivation necessitates purchasing LED grow lights, irrigation pumps and hydroponic systems to provide nutrients and water. Moreover, you’ll need fans, an exhaust system, dehumidifiers, and CO2 burners for your ventilation system and proper airflow.

Using vertical farming in your professional grow room eliminates the heavy use of herbicides, fertilizers, and pesticides which can be pricey and impair the quality of cannabis crops. Moreover, you can produce crops with 70 – 95 less water than in conventional cultivation, depending on the growing system. Vertical farming also proves superior to greenhouses in the yield produced per litre of water for a square metre of land.

Indoor vertical growing systems include;

- Hydroponics – Hydroponics is a vertical growing technology widely employed in vertical farms that involve growing plants in a nutrient solution.

- Aeroponics – Aeroponics is a vertical growing technique in which plants are grown in an air/ mist environment.

- Aquaponics – It’s a type of farming that involves a symbiotic relationship between fish and plants. Fish create nutrient-rich excrement for crops, and the crops purify the fish’s water.

- Soil – Even though vertical farming removes the need for soil, it remains a suitable medium for growing crops. Moreover, you can sterilize soil using hydrogen peroxide for indoor commercial cultivation, and there are natural alternatives to soil like coconut husks.

As cannabis legalization spreads, vertical farming proves as the preferable method for growing cannabis. CEA equips your commercial grow room with the technology it needs to achieve cannabis growing regulations such as seed-to-sale tracking.

This means that vertical farming allows for greater control (by automation) over the practicality and profitability of cannabis production.

Pros and Cons of Vertical Farming for Your Commercial Grow Room

Vertical farming technology has much to offer for a cannabis commercial grow room operation. Then again, some setbacks come with the technology. Here are a few things to consider when deciding to grow up.

Advantages of Vertical Farming for Your Commercial Grow Room

1. Customization

Vertical farming helps create a professional grow room as the systems can be configured to fit the available grow space. A vertical system can be easily adapted for your commercial grow space, whether in a shipping container, warehouse or skyscraper.

Most vertical systems providers bring in designers and advisors to assist in developing the ideal custom industrial size solution for your cannabis operation.

2. Automation

Vertical farming allows growers to automate cultivation equipment, resulting in higher-quality yields. Whether you need partial or complete automation, there are a variety of solutions to help control the irrigation, lighting, humidity, ventilation and fertigation for your crops.

This helps save on labor costs and time by eliminating repetitive processes and allowing your employees to focus on the critical tasks.

3. Maximizing Energy Utilization

Where you’ve previously invested in quality growing equipment but employed horizontal racks, switching to vertical grow racks will allow you to get more out of your equipment.

Vertical growing systems allow for good airflow while increasing output per square foot, resulting in healthier, more nutritious plants with better yields.

4. Plant Year-Round

Since you are planting indoors and in a controlled environment, whether it’s summer or winter outside, the inside environment is ideal for plant growth. Severe weather conditions can’t affect your plants, allowing consistent harvests throughout the year, improving profitability.

5. High-Quality Crops and More Yields

With the elimination of soil as the only grow medium, the plants are cleaner and easier to process. Crops are also kept free from pesticides, herbicides and most other chemicals, helping meet cannabis cultivation standards.

On the other hand, the stacked layers allow for space utilization both vertically and horizontally. This means you can have 4-6 acres in a single indoor acre and increase yield by over 200% for a particular space.

6. Sustainable and Environment-Friendly

Indoor vertical farming is primarily done in urban setups. The proximity to the consumer eliminates the cost of transportation of produce. Moreover, the products are within easy reach of consumers, increasing product freshness and allowing growers to make more money from their products.

Disadvantages of Vertical Farming for Your Commercial Grow Room

1. Not Sustainable for Small-Scale Farming

Vertical farming systems are great for all operation sizes; however commercial grow rooms benefit the most from this innovation. All the same, there is vertical growing equipment like tabletop caster units that can comfortably accommodate vertical growing for a household grow.

A professional grow room entails massive spaces that can support multiple tiers resulting in increased yields associated with vertical grow systems.

2. High Initial Cost

The purchase of vertical growing and environment control equipment can prove expensive. However, vertical farming has a good return on investment, making it beneficial in the long run.

3. It’s an Emerging Technology

There’s a demand to improve various aspects of vertical farming. For example, the multiple tiers can make it cumbersome to reach the plants; therefore, solutions like the mezzanine walkway are needed.

Notably, many other problems may arise, affecting the effective use of the cultivation method. Fortunately, companies like MMI Agriculture are investing in the field and developing solutions to streamline the industry.

What are the various solutions/ equipment available for commercial vertical farming?

Indoor Vertical Farming Equipment for Sale for Your Indoor Commercial Grow Room

Not all vertical farming equipment is the same. You need to source yours from the best providers. Some of the vertical equipment you can use to equip your room include;

1. Vertical Grow Racks For Your Indoor Commercial Grow Room

These are stacked shelving ideal for a commercial grow room. They are made of 16 gauge steel braced with steel cross and diagonal beams, making them among the strongest uprights in the market.

2. Mobile Carriages

These are vertical farming solutions that help maximize space by removing static aisles, and increasing productivity and available grow space.

3. Elevated Decking

This vertical farming solution specific to MMI Agriculture allows for easier access to plants located on higher elevations.

4. ABS Grow Trays

These are hydroponic trays made with strong and durable ABS plastic that allow you to plant crops on your vertical shelving with ease. These trays have a drainage grid that keeps water and nutrients flowing.

5. Tabletop Caster Units

These tables help take advantage of and utilize space that would be too small for a mobile system. They are customizable and mobile, making them perfect for a medium-sized operation.

Partner With the Right Installer for a Money-Saving Vertical System for Your Commercial Grow Room

Vertical farming systems are the best fit for a commercial grow room. It may be a developing technology, but it has proved effective in increasing yield for a particular grow space.

MMI Agriculture is a seasoned vertical system installer with a reputation for innovation and unmatched customer service.

We have the industry’s most sought-after vertical equipment, which comes with a 10-year warranty. We take pleasure in providing excellent service and vertical system installation knowledge.

Request a quote and enjoy a smooth transition into vertical farming.