Tips to Power-up Your Cannabis Grow House Design

Running a lucrative cannabis indoor facility demands a cannabis grow house design that supports your workflow. The US cannabis market is lucrative, valued at USD 13.2 billion in 2022 and expected to reach 40.1 billion by 2023.

Despite the large market size, different players are looking to get a piece of the pie, creating high competition in the industry. Competition shrinks the profit margins for companies unless you are efficiently producing quality (Grade A) cannabis.

Indoor vertical cannabis cultivation provides an opportunity to consistently produce premium cannabis. However, if your facility lacks a proper cannabis grow house design you may not meet your business goals.

Commercial indoor cannabis growing is done in warehouses, skyscrapers, or even shipping containers. Each structure presents unique design challenges.

A warehouse grow room gives the farmer flexibility to install the necessary climate equipment and vertical growing systems.

What Is a Cannabis Warehouse Grow Room?

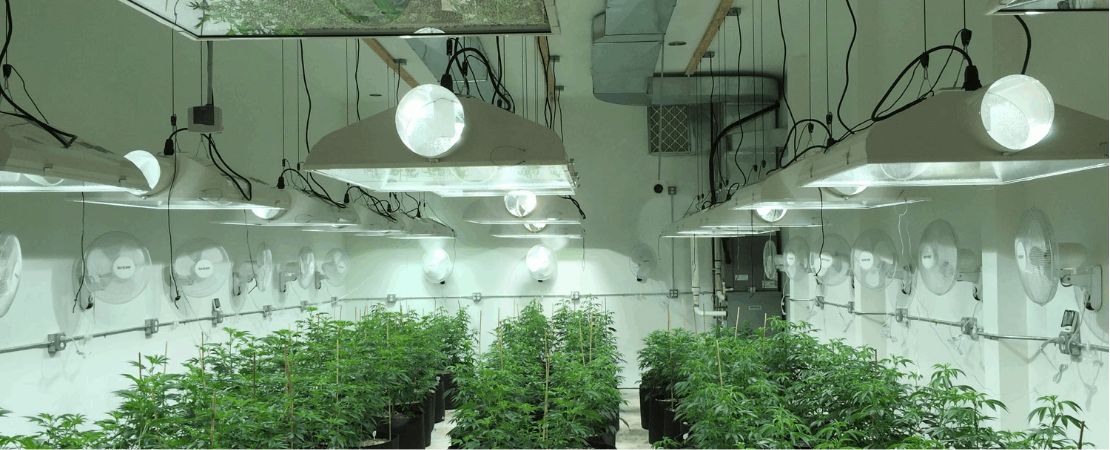

A cannabis warehouse grow room is an agricultural containment room in which cannabis (clones, seedings, and flowers) is grown under controlled environmental conditions.

The structures can be set up in any climate or environment as the grower has control over environmental factors like humidity, lighting, temperature, and airflow.

There are two approaches to acquiring a warehouse grow room. You can either build one from the ground up or lease a space. When deliberating on these options consulting with a professional is key to success.

Notably, building a warehouse for cannabis cultivation is expensive, time-consuming, and hectic trying to acquire permits. Nevertheless, should you manage to build there’s the advantage of having a space perfectly designed for your indoor growing equipment.

On the other hand, you can lease a warehouse to grow cannabis. Leasing a space saves time on acquiring permits and getting the project up and running.

One downside is that your cannabis grow house design needs to be adjusted to work in the existing structure. This can present a slight headache to the designers but not outside the scope of possibility.

The warehouse grow room design needs to be next to perfect to ensure a successful operation.

The ideal cannabis grow house design is dependent on two factors; your plans for installing vertical growing equipment and the design team for your warehouse grow room design.

Top Considerations for a Profitable Cannabis Grow House Design.

In cannabis cultivation, the process spans various phases such as cloning, flowering, harvesting, and drying. When planning out your warehouse you first need to have sections for each of these phases spelled out.

It’s recommended to have a separate room for cloning, seedlings/ flowering stage, and drying the cannabis.

Moreover, where space allows, you can further divide the flower rooms.

Dividing the flower rooms isn’t a necessity but it opens up room for experimentation with new varieties or treatment protocols. Also, it helps with containing diseases or pest outbreaks.

Then again, purchase appropriately sized airflow equipment for your operation. Undersized equipment can lead to high energy costs as they work hard to regulate the environmental conditions.

Furthermore, undersized HVACs and ACs result in inconsistent environmental conditions such as extreme levels of humidity or temperature affecting the quantity and quality of yields.

Various equipment-driven factors that determine the success of your cannabis grow house design.

1. Cannabis Grow House Design: Lighting

The cannabis plants need to get light at the appropriate duration and frequency.

Cannabis plants during the vegetative stage need 18 hours of light. Cannabis requires 12 hours of light to enter the flowering stage. To ensure consistency, growers may need to install controllers that automate the transitions between light and darkness durations.

Moreover, have a space between the light fixture and your canopies. The grow lights and mature plants should be 1-3 feet apart (depending on the type of light) to avoid scorching the plants.

To avoid scorching the plants you need customized vertical growing systems. An experienced company should customize the vertical systems to your cannabis variety whether growing Indica, Sativa, or Hybrid varieties. They each grow to a particular height which determines the dimension of your vertical systems.

2. Cannabis Grow House Design; Vertical Growing Systems

A warehouse grow room should resemble a manufacturing factory. A good warehouse grow room design should produce high amounts of cannabis plants in respect to the available space.

Vertical growing systems provide an opportunity to increase the canopy per square foot by utilizing the overhead space.

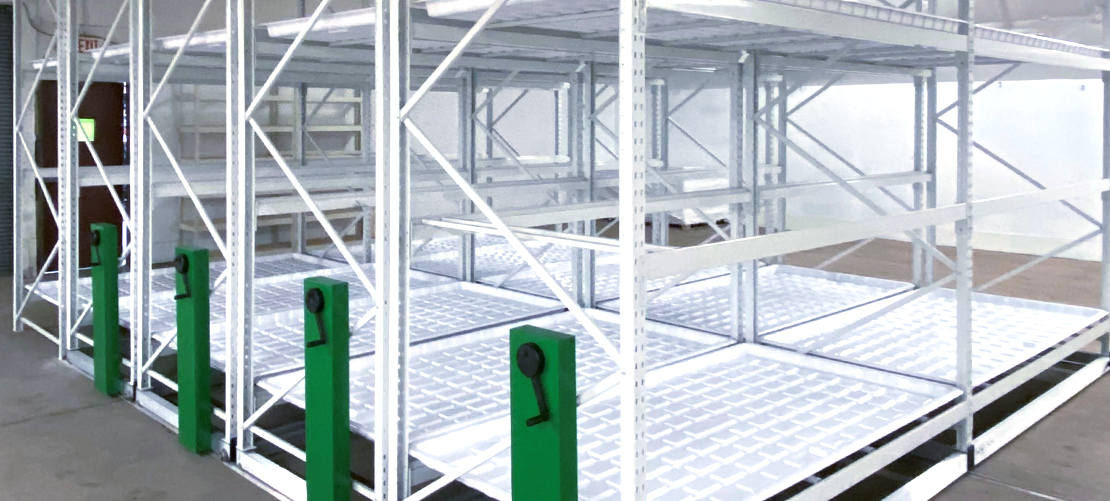

Vertical systems are multi-tier racks that can house your canopies, lighting and HVAC equipment, and irrigation systems.

There are a variety of vertical grow rack systems that can be customized to work for your cannabis grow house design.

First, we have the vertical grow racks. These are sturdy systems made of 14 gauge steel to support your plants, equipment, and workers as they tend to your plants.

They also have rebars to easily support your plant laden grow trays in addition to hung light fixtures. Conversely, you can have wire decking instead of rebars to also support your cannabis post-harvest efforts.

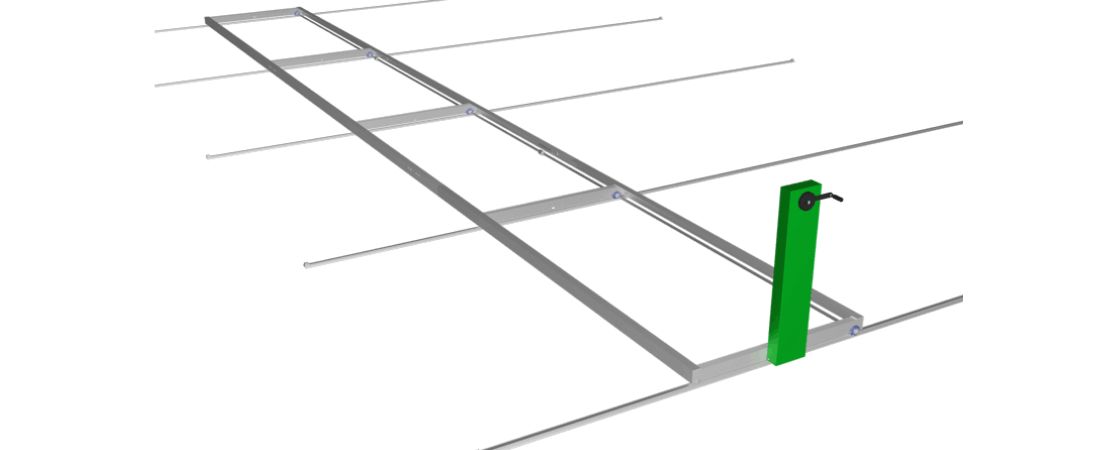

Second is our mobile carriages. These systems help utilize up to 90% of your grow space by eliminating static aisles. These heavy-duty vertical growing systems support up to 1400 pounds per linear square foot.

Their span/width is ergonomics-centered to ensure efficiency during plant care and harvesting. The mobile carriages are fitted with different gear ratios to move loads of all sizes with one hand.

Installing vertical systems isn’t a one size fits all approach, you need a design for every grow space.

The design work is also unique for your lighting, irrigation systems, and air circulation systems. You need to identify a company well versed with each of these intricate systems to ensure a working warehouse grow room design.

3. Cannabis Grow House Design; Floor Plan Layout and Indoor Grow Room Systems Design

One company cannot meet the requirements for the ideal cannabis grow house design. A cannabis grow room comprises many systems that require a variety of specialized services/companies.

These companies, also referred to as contractors or agencies, can be classified according to their roles in developing a credible warehouse grow room design.

- Cultivation Consultant

Cultivation consultants give you an overview of your cultivation project. They can help you identify the various cultivation methods, and instruct on streamlining workflow and everyday operations.

- The Cannabis Grow Space Architect

An architect needs to be licensed and at least versed in cannabis facility design for a proper layout. They should detail where to locate the growing rooms and drying rooms with an efficient workflow in mind.

- Mechanical Engineer

Getting your airflow equipment wrong could be detrimental to your indoor growing efforts. You need a mechanical engineer to design your electrical, plumbing, and environmental controls.

- Vertical Systems Specialist (Racking and Benching Installation Company)

Vertical growing systems are a capital-intensive part of your indoor grow op. As such, you need an experienced vertical growing systems installation company to ensure optimal use of space while keeping costs down.

MMI Agriculture is an experienced vertical systems installation company specializing in supplying and installing quality vertical growing systems. We support the grower’s efforts by providing a free floor plan drawing. Moreover, we perform capacity evaluations to help you monitor your business goals.

- Climate Conditioning Equipment Companies

Good airflow at the various stages of plant growth is crucial. Sourcing a HVAC company will help you get the appropriate equipment for healthy plant growth.

You also need to acquire the appropriate lights for your cannabis plant. Some varieties prosper under HID lights and other LED lights. Each type of light affects your costs and plant health.

Foster an Intelligent Cannabis Grow House Design With MMI Agriculture

An intelligent cannabis grow house design is dependent on getting a good design team and plans for your indoor grow systems.

A warehouse grow room is a pretty big grow space and with the right design can result in great gains.

At MMI Agriculture we are about getting you started and running with vertical growing systems.

We offer various preliminary services and supply reliable vertical grow racks to set you up for success. Contact us today for a quote.